lab testing

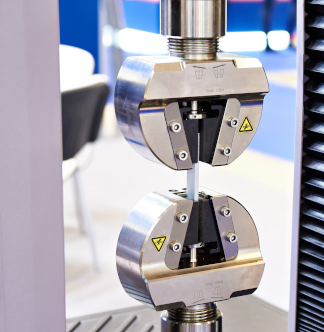

the importance of testing your flexible polythene products

flexible polythene products are widely used across various industries due to their versatility, durability, and cost-effectiveness. from packaging materials to protective films, the quality of these products is crucial for ensuring performance and reliability. to achieve the best results, it is essential to have specialised lab equipment to test key properties such as thickness, strength, elongation, tear resistance, and corona treatment levels.

armourthene® is fully tested and monitored so that we maintain the attributes we tell you about. users of polythene packaging need consistent products, especially in a modern automated environment.